Productive metrology: The relation between uncertainty and economic benefit

In this second post about productive metrology, we will discuss how a measurement uncertainty can affect the economic benefit of metrology.

In this second post about productive metrology, we will discuss how a measurement uncertainty can affect the economic benefit of metrology.

In the previous post, we have discussed the philosophical background of how metrology is considered to be a productive activity instead of a costly activity.

A measurement process can add “value” to a product or/and process. This value adding activity depends on the uncertainty of measurement results.

The main goal of doing a measurement is to add quantified information from a previous understanding. This information addition is inversely proportional to the magnitude of the measurement uncertainty.

The smaller the measurement uncertainty, then the bigger the information gain obtained from the measurement activity.

It is worth noting that all measurements are wrong (meaning, different from the true value). However, the most important thing is that we have to know how wrong we are (how much deviate we are from the true value).

That is, measurement uncertainty is a measure of how wrong or how convincing our measurements are.

Let’s go into the discussion!

READ MORE: Productive metrology: The role of metrology to transform data into know-how or wisdom

- Grammar Rules: Everything you need to know but never learnt in school – A book about how to make efficient and concise sentences to writing with military precision!

The role of uncertainty to determine the economic benefit of metrology

As being mentioned before, the smaller the uncertainty of a measurement, the larger the information gain obtained from the measurement.

However, we must be careful to reduce measurement uncertainty if we want to get the optimal economic benefit.

There is a limit where we can reduce the measurement uncertainty too much exceeding our required precision (related to its measurement tolerance) so that we will lose the economic benefit of the measurement.

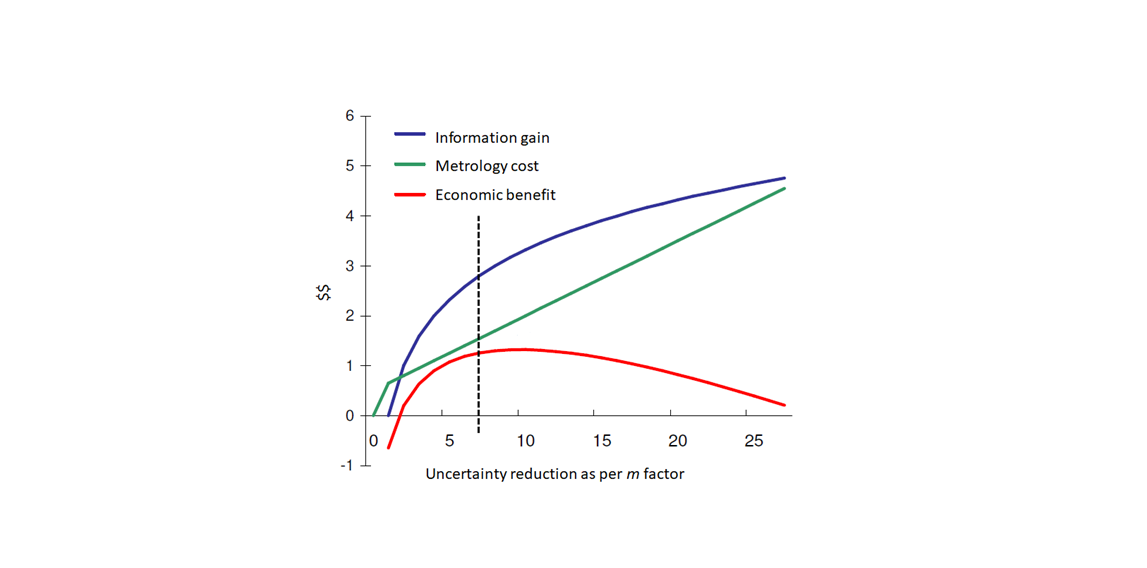

Figure 1 below shows the illustration of how measurement uncertainty affects the economic benefit of a measurement. In Figure 1, the horizontal axis described how much we reduce our measurement uncertainty, and the vertical axis is the cost/benefit of metrology or a measurement activity.

From figure 1, there are three relationships that are coupled each other. The relationships are information gain, the cost of metrology (measurement activity) and the economic benefit from the measurement activity.

How good our investment in metrology can be defined in three principal conditions (figure 1), they are:

- $m=1$: Investment in metrology does not add any new information (no information gain) because the measurement uncertainty is too large such that our confidence in the measurement is very low. In this condition, metrology is as “cost-centre”.

- $m~10$: Investment in metrology can provide significant and meaningful information gain on a product and/or process. The measurement uncertainty is just enough to gain confidence in the measurement (with respect to its tolerance). This measurement activity can then add profit by reducing scraped parts or reducing bad parts sent to customers. In this condition, metrology is as “profit-centre” (productive).

- $m>10$: Investment in metrology is too large and is not proportional with the gain of new information. The reason is that to lower the measurement uncertainty, the cost of doing the measurement will increase non-linearly. This too low measurement uncertainty is an expensive measurement, such as using an over-qualified instruments or too long measurement processes. In this condition, metrology is as “cost-centre”.

READ MORE: The role of measurement uncertainty in quality inspection

- Numerical Methods for Scientific Computing - A book that explains the algorithm behind scientific computing

The high cost of late defect detection

Productive metrology can have a significant gain if we can detect defects of a product or process as early as possible.

The position of a measurement activity in a process chain (for example a production process) can significantly determine the value of economic benefit that can be gained from the measurement activity.

Figure 2 below shows the description of how late defect detection can significantly increase production cost. Meanwhile, very common, measurements are overlooked at the early stage of a process so that all defects will be carried out and added up to the final process or product.

At this period, a repair or problem-solving activity will have a very significant high cost.

Based on statistics, for production process of a product, a total of 75% of mistakes or defects (such as design mistakes, manufacturing defects, assembly defects, and other defects) happens in the early phase of the process.

Out of 80% from the total 75% defects or mistakes are commonly not detected until a part reach its final process or maybe until the part is sent to a customer. At this period, the cost to repair the part or product becomes very high, or very often, the part or product needs to be scrapped.

There are many reasons of why most of the defects are not detected at the early stage. For example, there is insufficient measurements at the early stage of the production (such as do not implement an in-line measurement system) or simply because a measurement activity is considered as costly activity and cannot add value to the process.

This mind set should be changed!

There is a general rule. That is, the cost of repair of a defect will increase 10 times for each late detection from one previous phase.

Hence, early measurement activities are vital to improve the economic benefit of metrology.

READ MORE: The fundamental concept of metrology

Conclusion

In this post, we have discussed the role of uncertainty in determining the economic benefit of metrology. In addition, we also discussed how the later a defect of process or product is detected, then the larger the cost it will cause.

A measurement with very large uncertainty will cause the measurement is useless since the measurement will not give more information gain.

However, if the measurement uncertainty is too small beyond the required tolerance. Hence, this measurement will be very costly and will not justify the information gain that can be obtained.

Those two conditions cause the metrology as “cost-centre”.

That is, for metrology to be as “profit-centre” (productive), our measurement should have measurement uncertainty just enough to justify the required tolerance. At this condition, the cost of metrology can be justified for the information gain obtained from the measurement and can give value to a product or process.

Reference

[1] Kunzmann, H., Pfeifer, T., Schmitt, R., Schwenke, H. and Weckenmann, A., 2005. Productive metrology-adding value to manufacture. CIRP annals, 54(2), pp.155-168.

You may find some interesting items by shopping here.

- Simple rule: How to thrive in a complex world – A book explaining how we navigate in a situation or a problem, where we do not really understand, and find an effective solution.